Advancements in 5-Axis CNC Machining Technology

The Evolution of 5-Axis Machining

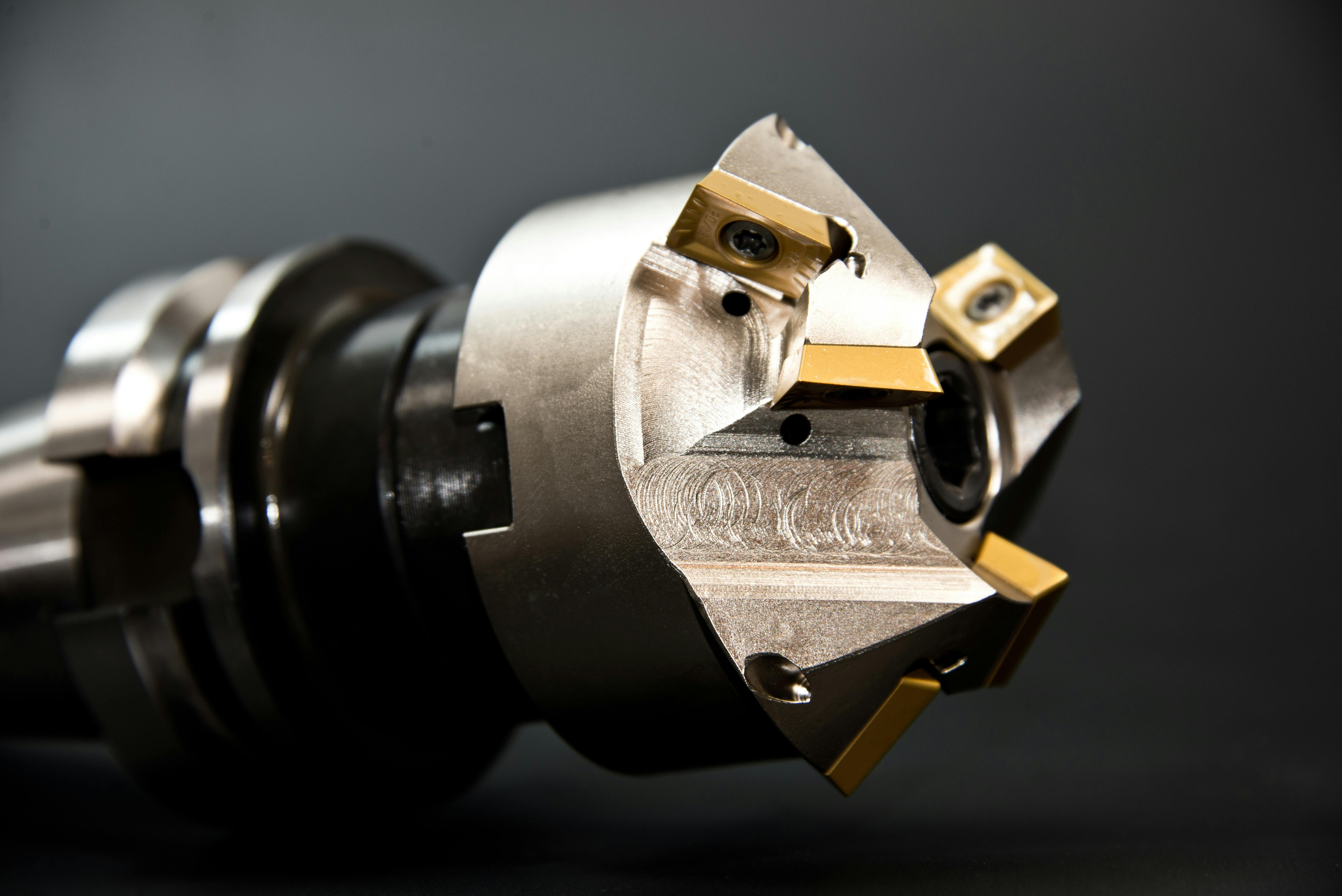

5-axis CNC machining represents a significant leap forward in manufacturing technology, allowing for the production of complex components in a single setup. This technology has evolved rapidly over the past decade, offering manufacturers unprecedented levels of precision and efficiency.

Key Benefits of 5-Axis Technology

1. Complex Geometries in Single Setup

5-axis machines can approach the workpiece from five different directions simultaneously, eliminating the need for multiple setups and reducing production time by up to 70%.

2. Improved Surface Finish

The ability to maintain optimal tool orientation throughout the machining process results in superior surface finishes and reduced need for secondary operations.

3. Enhanced Accuracy and Precision

By minimizing workpiece handling and setup changes, 5-axis machining reduces cumulative errors and improves overall dimensional accuracy.

4. Reduced Production Time

Complex parts that previously required multiple operations across different machines can now be completed in a single setup, dramatically reducing lead times.

Applications in Heavy Industries

5-axis CNC machining has found particular success in:

- Aerospace Components: Turbine blades, engine parts, and structural components

- Medical Implants: Complex orthopedic implants and surgical instruments

- Automotive: Engine blocks, transmission components, and suspension parts

- Mold Making: Complex injection molds and die-casting tools

Future Trends in 5-Axis Machining

The future of 5-axis machining includes:

- Integration with AI and machine learning for predictive maintenance

- Enhanced automation with robotic loading systems

- Improved energy efficiency through smart power management

- Real-time monitoring and quality control systems

At Prime Source Industries, we've invested in state-of-the-art 5-axis CNC machines to provide our clients with the most advanced manufacturing capabilities available. Our technical team has extensive experience in programming and operating these complex systems to deliver precision components for demanding industrial applications.